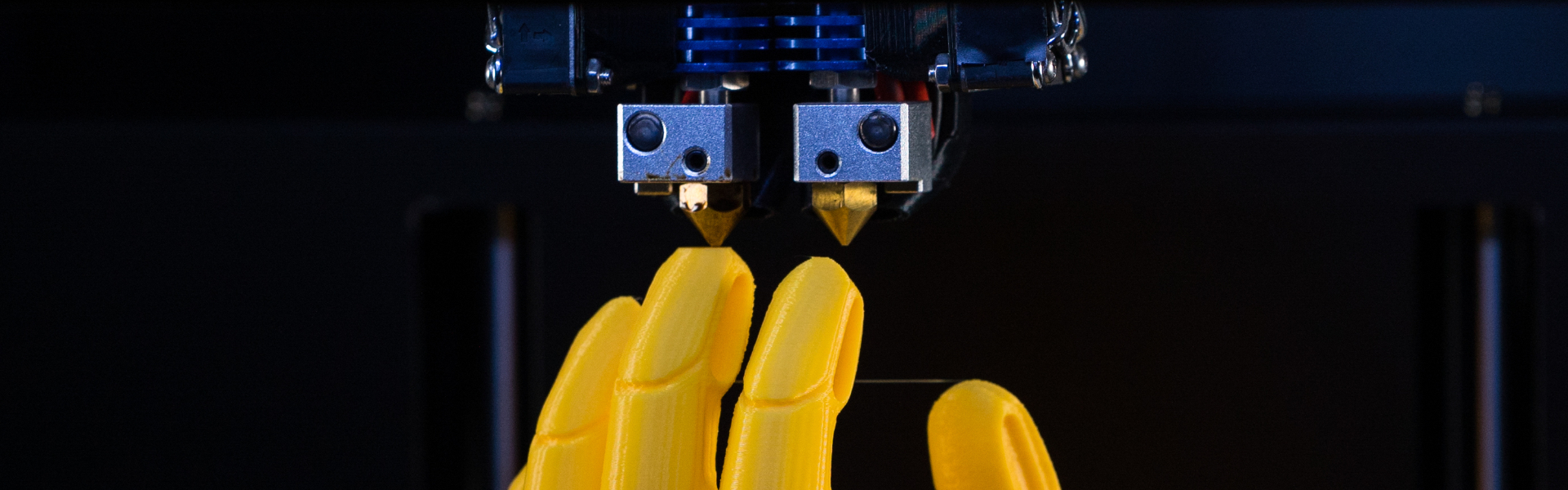

Additive manufacturing is a manufacturing method that consists of adding material to build parts. It gives the possibility of creating parts with advanced functionalities, thanks to the ease of design that allows the integration of weight reduction techniques, customization of parts, cost reduction, thus obtaining industrial improvements.

The mission of the Leitat-led node is to accelerate the adoption and development of additive manufacturing and 3D printing technologies by industry and business, as an alternative way to design, develop and produce new products, in order to increase the level of competitiveness of companies and contribute to a more sustainable industry and world.

Main technologies

To carry it out, we assess you on the following technologies:

- AM/3D Printing Design

- Advanced materials

- Digital AM/3DP Factory

- AM/3DP Final

- Consulting AM/3DP

Infrastructures

We have centres and infrastructures of renowned reputation:

- Metals Lab (powder)

- Polymers Lab (filaments, powder and resins)

- Characterization Materials Lab

- Post Processing Area

- 3DP Medical Lab

Informes Tecnològics

Consulta els informes tecnològics publicats des d’ACCIÓ:

Success stories

Success Case 3D printing: Travel Sax, the smallest saxophone in the world

Success Case 3D printing: Manipulators and clamps for collaborative robots

Do you need more information?

Contact us and you will get a personalized answer to your needs.

Contactar

Additive manufacturing and 3D printing

Additive manufacturing and 3D printing